Footwear printing Compliance

Spinks world footwear printing inks follow all the footwear printing related Compliance

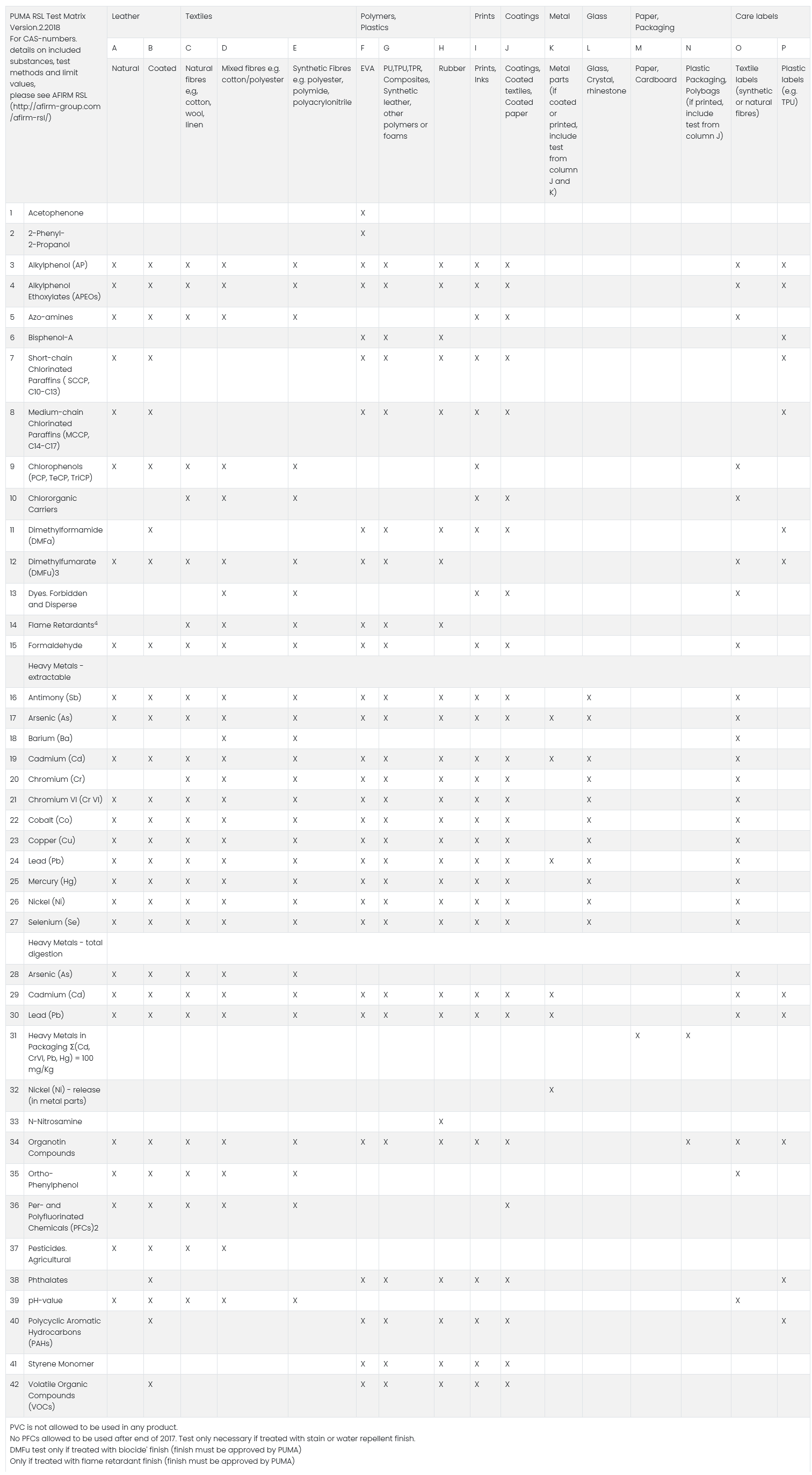

Restricted Substances List

PUMA has established and made some rules and regulations, i.e., RSL standards for PUMA manufacturers, distributors, and suppliers in the apparel and footwear supply chain. The AFIRM RSL refers to the raw material, inks, and consumables containing some harmful elements; these elements must be within a specific limit. These Limits and values are mentioned in AFIRM RSL.

The AFIRM RSL is available on their website in several languages here: http://www.afirm-group.com/afirm-rsl/. The AFIRM RSL is only applicable to all products and its raw material of PUMA. PUMA needs all the raw materials and components of its products to be tested against the toxic restricted, harmful elements present in the Products before they are used to develop the final finished item. The Vary second stage of the Rsl testing procedure includes random testing on any final product. As one of the global brands, PUMA can never violate safety regulations, which is a must to develop the product. Any violation leads to endangering life and affecting customers' health, Recalls, loss of customers' faith in the brand, and it ruins the image of the brand and its value. Therefore, PUMA has implemented strict punishment and huge penalties that don't follow RSL regulation and always expects all its raw material suppliers to follow RSL compliance on the materials they supply PUMA strictly.

For developing the final product

Spinks world Supplies RSL compliant Footwear inks and heat transfer for the footwear industry and provides all the printing-related Solutions for Footwear.

Apart from the toxic, harmful restricted elements mentioned in AFIRM RSL, there are some extra parameters that PUMA restricts for its products and requirements for specific applications. The restrictions on harmful chemicals and Products are PVC, Per- and Polyfluorinated Chemicals (PFCs), adhesives, biocides, nanomaterials, odor, and Volatile Organic Compounds (VOCs).

REACH

All PUMA products that include footwear, apparels, and many more must follow all regulations that are REGULATION (EC) No 1907/2006 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 18 December 2006 concerning the Registration, validation, Evaluation, verification, Authorization, and Restriction of Chemicals (REACH).

PUMA restricts any Substances of Very High Concern (SVHC) present in PUMA products and materials above a concentration of 0.1% (w/w).

The "Candidate list of substances of profound concern for Authorization" can be found under those mentioned above. This PUMA test matrix mentioned below has the complete list of the chemical with the known risk of contaminated material.

Ban of Polyvinylchloride (PVC) in Footwear inks

PUMA has banned PVC completely in any PUMA products (including components) since 2003.

The PUMA PVC-free regulatory policy is verified and validated using the "Beilstein Test" test method as qualitative analysis and FTIR test method to confirm results if tested positive.

Ban of Per- and Polyfluorinated Chemicals (PFCs) in footwear inks

PUMA has restricted the use of long-chain polymer PFCs since 2015 and Polyfluorinated chemicals from January 2018 onwards. In any of the exceptional cases required to be signed off in writing by the PUMA Sustainability department.

Polyfluorinated chemicals are very obviously utilized chemicals providing a Water Repellent function that makes the top surface area of a fabric or product water, oil, and dirt repulsive. Polyfluorinated chemicals are commonly used for the production of membranes made of Polytetrafluoroethylene (PTFE).

Restriction and banning of Volatile Organic Compounds (VOCs) in Adhesives

PUMA has aimed to reduce the Volatile organic compound per pair of footwear (that may be a shoe, a flip-flop, sandal, or floaters) to below 15 grams by 2020.

This will only be achieved by increasing the use of all water-based inks, thinner, hardener, adhesive, retarder, or cleaner.

Puma Vendors and suppliers must ask the PUMA factory production and development experts to sign-off the use of any solvent-based adhesives if it is required for some particular typical applications. PUMA check the VOC consumption data from time to time from the factories. Therefore, all the Puma footwear supplier has to make a file that needs to be presented, showing how the volatile organic compound is present per unit production. Chemical Inventory must be on the check, which is the part of inspection for all those PUME Suppliers.

Complete abolishing the usage of Dimethylformamide (DMF)

Polyurethane (PU) is a widely used raw material in most PUMA products the includes shoes, bags, and balls.PU as a raw material a polymer is developed either by water-based technology or DMFA based technology Dimethylformamide (DMFa) is commonly used in PU coatings and PU synthetic leather production and development.

However, DMFa is labeled as a harmful toxin raw material, and this chemical is listed as carcinogenic by the California Proposition 65 regulation. EU REACH also has mentioned DMFa as Substances of Very High Concern(SVHC). With the current policy of AFIRM RSL, it limits DMFa values to 500ppm. PUMA Demands and keeps a strict regulation on its suppliers to use DMFa free and water-based technologies. Besides, PUMA strongly recommends adopting Bluesign BSSL limit value for DMFa of 50 ppm as a proactive approach to ensure full legal compliance and maximum consumer safety.

And it is strictly stated that in the pace of DMFa, the DMAC element or other toxic, harmful solvents is not at all the recommended solution as DMAC chemical is also classified as a poisonous toxic compound by REACH & California Proposition 65.

Materials with Food or Mouth Contact

The PUMA products, which are commonly in contact with food or that goes the mouth, for example, water bottles, must fulfill some of the criteria. The following European regulations are

Applied on those products and must be followed as well

- Regulation (EC) No 1935/2004, which covers general rules applicable to all materials and articles that commonly come into contact with food-related stuff

- GMP Regulation (EC) No 2023/2006 (Good Manufacturing Practice)

- Regulation (EC) No 10/2011, applies to plastic materials and product which commonly come in contact with food and mouth

- BfR Recommendations on Food Contact Materials

Restricted Biocidal finish

biocidal finishes on PUMA products are entirely restricted. In exceptional cases, the usage might be allowed by PUMA to reach some typical performance. E.g., anti-microbial or anti-odor. Approval by PUMA is a must before use and meets the requirements of the Biocidal.

Products Regulation (BPR, Regulation (EU) 528/2012) as well as the US EPA "Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)."The Regulation mentioned in the above statements must be taken care of very precisely.

Odor

The raw materials and product should not librate abnormal smell (non-material or not product-specific).

Suppose the peculiar smell is detected at the time of manufacturing. In that case, the materials must be tested in a laboratory, and it must be ensured all the abnormal smell of material is cleaned and whipped out thoroughly. Odor (sensory) testing must be done according to norm SNR 195651:2015-09.

Assessing footwear in line With EN 71 toy safety standards

Explicitly stating how these standards refer to specific types of children's clothing and footwear, as well as how those items are tested.

Although footwear does not come into the concept of a toy (and many children's items do not either), the safety criteria for toys detailed in the EN 71 set of rules are also viewed as good practice since they take into consideration children's instinctive behavior. As an EU Notified Body, Intertek can guide you through what you need to do to comply with the EU Toy Safety Directive's EN 71-3:2019, highlight the highest areas of risk, and pinpoint which chemicals and toxic elements are likely to be found in your products.

Inks testing includes :EN 71-3 Complete Migratable Screening – it is indeed a provisional screening that considers the overall migration of all heavy metal families identified. As a result, a concise report is generated that can be used to show compliance. Roughly 90% of all sample requests should always include this move to be compliant.

EN 71-3 Risk Assessment – This service can be used as an original substance risk assessment prior to inspection, or as a follow-up approach if the initial screening indicates the likelihood of noncompliance. Using historical evidence, the scientific staff calculates the probability of each heavy metal's existence.

Qualification Review is a follow-up evaluation for the estimated 5% of items that did not meet requirements after the preliminary screening.

Nike Corporate RSL Implementation Guide

Inks, Paints, Pigments, Adhesives, Screen Print Inks, Heat Transfers, Dimension Welds, and related embellishments are associated with elevated risk for RSL non-compliance for the purposes of this paper. Prior to use, these components MUST be tested. Testing must be performed in the "as applied" state, for example, cured ink, dry paint, etc.

Prior to application to every component, ALL paints, inks, and pigments must be checked annually and obtain an RSL PASS result. They must be retested if the composition is changed.

A color scheme is specified in RSL as the collection of base colors plus any additives or thinners used to blend colors. If a supplier regularly uses the same color scheme, tests will prove that the different base colors and additives of the paint or ink are RSL compatible. A color scheme that is RSL compliant should be used to demonstrate that the colors combined entirely from the system's components are RSL compliant. Once a color scheme is RSL compatible (all base colors and additives pass the RSL test), There can be no replacements of any of the base colors or ingredients without retesting.

Reference link: https://www.greenscreenchemicals.org/images/ee_images/uploads/resources/NIKE_INC_Restricted_Substances_Guidance_Aug_2011.pdf

A-01 Adidas Policy : Control and Monitoring of Hazardous Substances

The apparel company associates must ensure that Adidas's goods are fully compliant with current local environmental and product quality laws and regulations.

Partners in the footwear industry must prevent the deliberate use of the substances specified in the A-01 criteria and adhere to best practice practices. Adidas actively monitors and controls quality conformity by performing content checks in independent labs.

Adidas actively encourages its corporate partners to take an active interest in reducing the environmental effects of the products they sell. Improving the environmental effect entails ensuring that the materials and components supplied are non-toxications in usage and are easily disposable, and that their use in manufactured products does not result in toxic releases or habitat harm. Strive to produce materials that are recyclable or biodegradable and manufactured from recycled and organic products.

Produce chemical parts and products in the most environmentally friendly manner possible, using the most advanced technologies.

Reference link: https://www.adidas-group.com/media/filer_public/60/a3/60a38e1d-90aa-43a0-a749-a8350099aaed/2020_adidas_product_safety_policy_a-01.pdf